meyer hardness test|hardness testing lab report : retailer extent any hardness test is arbitrary, but we shall here accept the view of O’Neill (1934) that the method of Meyer (1908) is the most satisfactory way of expressing results obtained with spherical indenters, and that the ultimate Meyer hardness, Pu> is the least unsatisfactory way of indicating hardness by means of a single constant. Discover the ultimate guide to steam (autoclave) sterilization for healthcare professionals. Learn the principles, processes, and critical role in patient care.

{plog:ftitle_list}

This chart summarizes the different ISO types of chemical indicators. It also .

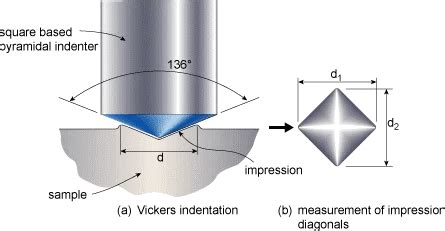

The Meyer hardness test is a hardness test based upon projected area of an impression. The hardness, H {\displaystyle H} , is defined as the maximum load, P max {\displaystyle .Meyer hardness testing has some advantages over Brinell hardness testing as follows: The Meyer hardness is less sensitive to the applied load than the Brinell hardness, as discussed above. The Meyer hardness is a more fundamental measure of indentation hardness because it is based on the projected area of the indentation rather than the surface . Hardness testing can be applied to various types of materials, some of which are listed below: Metals and alloys. Ceramics. Elastomers. Polymers and plastics. Films. Rocks and minerals. Importance of Hardness . The Vickers hardness is the load divided by the contacting surface area, while the Knoop hardness is the load divided by the projected area, and hence corresponds to the Meyer value. The hardness test is very easily conducted, but not so easily interpreted.

extent any hardness test is arbitrary, but we shall here accept the view of O’Neill (1934) that the method of Meyer (1908) is the most satisfactory way of expressing results obtained with spherical indenters, and that the ultimate Meyer hardness, Pu> is the least unsatisfactory way of indicating hardness by means of a single constant.

A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be .The Meyer hardness test is a hardness test based upon projected area of an impression. The hardness, , is defined as the maximum load, divided by the projected area of the indent, . This is a more fundamental measurement of hardness than other hardness tests which are based on the surface area of an indentation. The principle behind the test is that the mean pressure required .

anterior labral tear test trackid sp-006

Prosedur Hardness Test : 1. Brinell Hardness Test. Hal yang perlu diperhatikan pada saat pengujian hardness Brinell adalah sebagai berikut : Spesimen harus memenuhi persyaratan : – Rata dan halus. – Ketebalan minimal 6 mm. – Bisa ditumpu dengan baik dan permukaan uji harus horizontal.

This chapter discusses hardness testing. Hardness testing is a descriptive term for a number of methods for the measurement of the resistance of a surface to the action of a body which is forced into it under pressure or by means of an impact. . Meyer The hardness unit Meyer (HM) can be measured using Brinell equipment, where the projected . The force dependence of the ball indentation hardness can be described in many cases by MEYER's hardness law. The characteristic material parameters are the MEYER constant K and the MEYER exponent n. But often other simple measures of hardness are used for technical applications. Examples are the difference of hardness for two different loads . The Brinell, Vickers, Meyer, Rockwell, Shore, IHRD, Knoop, Buchholz, and nanoindentation methods used to measure the indentation hardness of materials at different scales are compared, and main issues and misconceptions in the understanding of these methods are comprehensively reviewed and discussed. Basic equations and parameters .

Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion resistance).

Meyer Hardness Test. A test to determine tendency of a metal to harden when deformed plastically. A series of indentations are made in the metal using a fixed-diameter ball and progressively increasing loads. Mf. The temperature at .The Brinell hardness test consists in indenting the metal surface with a 10-mm-diameter steel ball at a load of 3,000 kg mass (∼29400 N). . first increases with load and then decreases for still higher loads. The Meyer hardness is a more fundamental measure of indentation hardness; yet it is rarely used for practical hardness measurements. MEYER HARDNESS TESTING M FACTS The Meyer hardness is a more fundamental measure of indentation hardness. Based on the 'projected area of the surface area. The principle is that the mean pressure required to test the material is the measurement of the hardness of the material For a cold-worked material the Meyer hardness is essentially constant . Nanoindentation hardness tests are used to measure indentation hardness at the micro- and nanoscales and further to predict Vickers hardness on larger scales. Hence, the relationship between Vickers and nanoindentation hardness has gained considerable research interest. Here we introduce the concept of Meyer hardness as a mean contact pressure .

Meyer hardness test is a research topic. Over the lifetime, 427 publications have been published within this topic receiving 33559 citations. Popular works include An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments, The Hardness of Metals and more.hardness test and the tensile test measure the resistance of a metal to plastic flow, and results . where VHN is the Vickers Hardness number and n is the Meyer’s index. The 0.2 percent offset yield strength can be determined with good precision from Vickers hardness .

A method is described in which the Rockwell hardness machine is used to determine the Meyer hardness and Young's modulus of a material. Meyer hardness values so derived for a number of materials .Meyer's law is an empirical relation between the size of a hardness test indentation and the load required to leave the indentation. [1] The formula was devised by Eugene Meyer of the Materials Testing Laboratory at the Imperial School of Technology, Charlottenburg, Germany, circa . Hardness testing plays an important role in materials testing, quality control, and acceptance of components. We depend on the data to verify the heat treatment, structural integrity, and quality of components to determine if a material has the properties necessary for its intended use. Through the years, establishing means of increasingly more .2.2 Meyer Test Devised by Prof. Eugene Meyer in Germany in 1908, the test is based on the same Brinell test principle (Fig. 1), but the Meyer hardness number (MHN) is expressed as the indentation load L divided by the projected area A p of the indentation [14], MHN ¼ L A p ¼ 4L pd2 ð2Þ An advantage of the Meyer test is that it is less sensitive

It compares Brinell with Meyer hardness testing and hardness testing of fully cold worked metals with fully annealed metals. The article discusses the plastic deformation of ideal plastic metals under an indenter, by a flat punch, and by spherical indenters. The classification of the hardness tests using various criteria, including type of .The Meyer hardness test is a rarely used hardness test based upon projected area of an impression. This is a more fundamental measurement of hardness than other hardness tests which are based on the surface area of an indentation. The principle behind the test is that the mean pressure required to test the material is the measurement of the hardness of the material. Janka hardness is very comfortable for machine use and has been continuously improved [].However, accurate measurement of indentation force is somehow problematic with respect to controlling indentation depth, and the use of a type measure transfers its imperfections to or ().Another example of using the indentation projection area (i.e. the Meyer measure) is .

anterior labrum tear test

Meyer Hardness Number. The Meyer hardness number abbreviated as MHN is based on the same indentation test as the Brinell test, the only difference being that the indentation load F is divided by the projected area of the indentation. where P m is the mean contact pressure. Rockwell Hardness Number

We would like to show you a description here but the site won’t allow us.

test than in the simple compression test. The relation between the Meyer hardness and the uni-axial flow stress may be expressed as follows: H M ¼ Cr 1 ð4Þ where C is called the constraint factor for the hardness test. Experimentally, C approximates three for the Brinell, Vickers, and Knoop hardness tests. A central problem in the theory of .

anterior posterior labral tear test

vickers hardness test procedure pdf

Manufacturer and biological indicator product methods may vary in extraction techniques, as well as heat-shocking and incubation temperatures of different test organisms, and .

meyer hardness test|hardness testing lab report